This article on the Snapmaker forum outlines how to do it. https://forum.snapmaker.com/t/extruder-calibration-a-must/7724/33

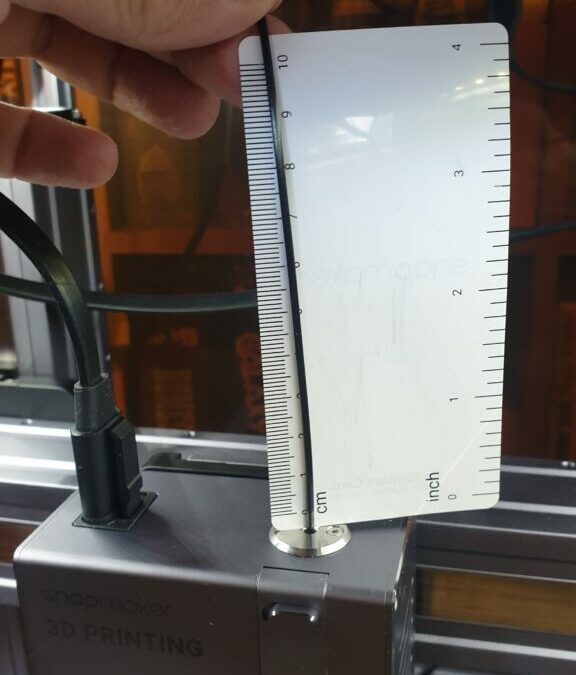

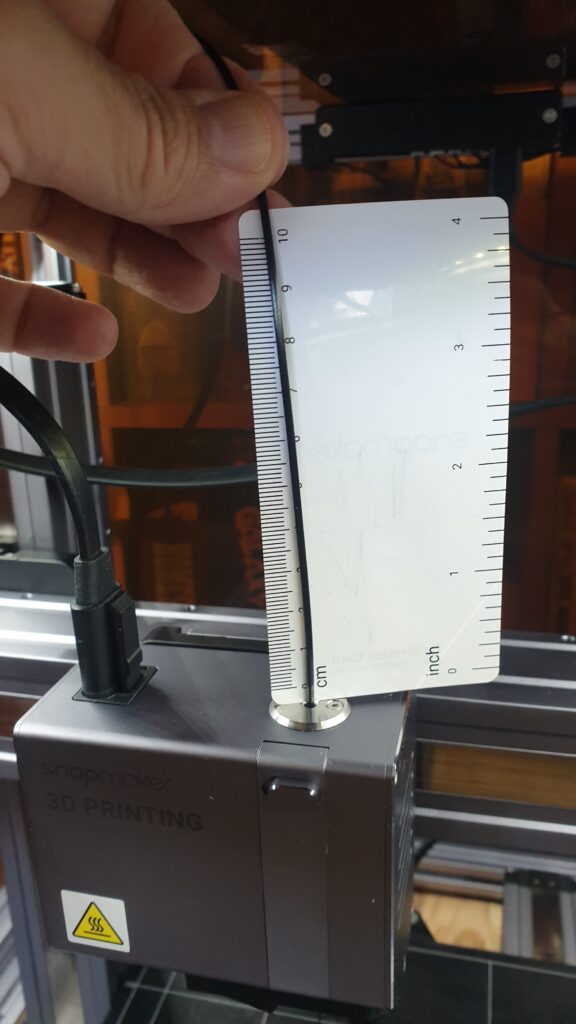

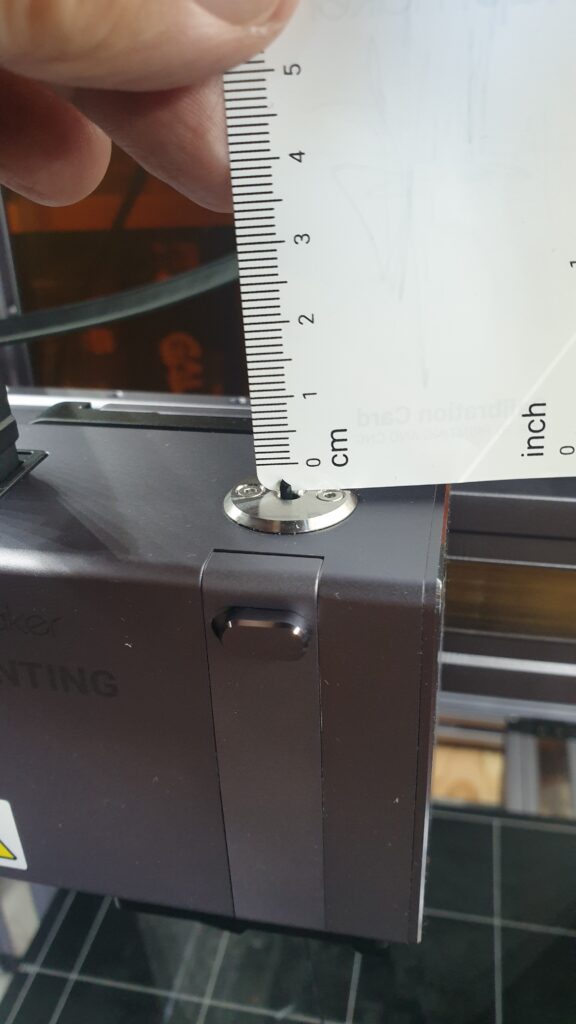

I use the calibration card to measure and cut the filament at 10 on the card, i.e 100mm plus the dead space before the 0. But since I measure the extruded distance also with this space it can be ignored.

Make sure the hot end has reached the correct temperature for the filament you are calibrating with. And issue the command to start feeding the 100mm of filament. Once that finished measure the amount of filament left.

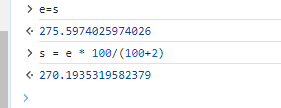

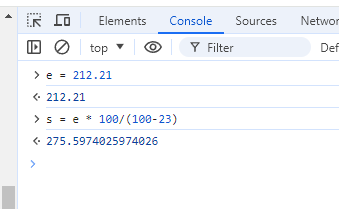

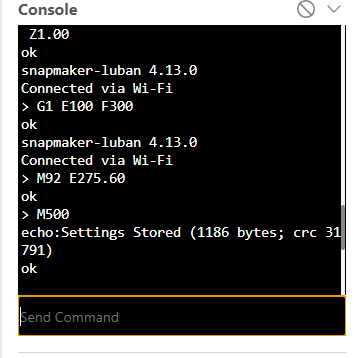

I had 23mm left this time. Then it is time to do the calculation. I find it easiest to start the developer tools in the browser. In the console there I just enter the expressions in the article.

Then use the Luban console to enter the newly calculated value and permanently store it. If you want to understand the M-commands like M92 this page was good, https://snapmaker.github.io/Documentation/gcode/M092

Finally make a test run with the same command that feeds 100mm of filament. Mine fed a few mm of extra filament.

This time I ignored the difference but if you want you can re-calibrate. Use your calculated S value as the new E in the calculation and enter how much filament that has been fed. Repeat until you are satisfied.